Defence & Aerospace

40 years of aviation experience

With over 40 years of aviation experience and AS9100-certified production, we develop, engineer and manufacture ultra-reliable parts and assemblies that comply with ITAR regulations and are fully traceable.

We efficiently scale from prototype to series production for mission-critical aerospace and defence applications.

Over the years, we have delivered innovative engineering and production services under strict international regulations and certifications, utilising reliable and market-specific knowledge within our robust and scalable supply chain.

Furthermore, we conduct annual audits and our quality management system is reviewed every three years. We specialise in opto-mechanics, mechatronics, and machining complex high-precision parts from a broad range of materials, including titanium and specialised aluminium super alloys. We often utilise 3D printing processes as a starting point for these complex parts and assemblies.

© Eric RAZ / AIRBUS Helicopters

Defence & Aerospace

40 years of aviation experience

© Eric RAZ / AIRBUS Helicopters

With over 40 years of aviation experience and AS9100-certified production, we develop, engineer and manufacture ultra-reliable parts and assemblies that comply with ITAR regulations and are fully traceable. We efficiently scale from prototype to series production for mission-critical aerospace and defence applications.

Over the years, we have delivered innovative engineering and production services under strict international regulations and certifications, utilising reliable and market-specific knowledge within our robust and scalable supply chain.

Furthermore, we conduct annual audits and our quality management system is reviewed every three years. We specialise in opto-mechanics, mechatronics, and machining complex high-precision parts from a broad range of materials, including titanium and specialised aluminium super alloys. We often utilise 3D printing processes as a starting point for these complex parts and assemblies.

Solutions

©Airbus SAS 2020

Aerospace

We are AS-9100 certified for the aerospace industry, and we adhere to strict procedures, including meticulous inspections and optimal traceability. Components from aeroplane structures, engine parts, and interior components can be subjected to thermal and surface treatments, as well as cleanroom cleaning, where we work closely with expert companies within our extensive network.

Air Defence Systems & Subcomponents

As airspace threats become more complex, radar systems, advanced guided platforms, counter-drone technologies, and unmanned aerial systems (UAS) play a critical role in safeguarding national security and operational sovereignty.

We collaborate with our customers to leverage our extensive experience and knowledge in assembling and machining complex, high-precision parts, utilising advanced tools and integrated control systems to ensure efficient, cost-effective, and error-free processes. We can test all assembled products and systems mechanically, electronically, and through software methods, and perform long-term tests over several days if necessary.

Optomechanics

Our extensive experience in developing and manufacturing optical systems incorporates lenses and precision components. The applications range from interferometry and marker detection to satellite communication modules, making these detection and communication systems increasingly accurate and robust.

During our design process, we utilise specialised ray tracing software, such as OpticStudio. In production and assembly, we employ advanced surface treatments and glueing techniques

Unmanned vehicles (UAV, UGV, USV, UUV)

Unmanned vehicles are vehicles that operate without a human on board, are controlled remotely, or are guided by automated systems. They are used in various forms across different domains, including unmanned aerial vehicles (UAVs, or drones) for tasks such as surveillance and delivery, unmanned ground vehicles (UGVs) for operations in rugged or hazardous terrain, unmanned surface vehicles (USVs) for water-based operations, and unmanned underwater vehicles (UUVs) for ocean exploration. Their use has expanded significantly from military applications to a wide range of civilian purposes, such as search and rescue, crop monitoring, and environmental research.

We support clients in this emerging sector with our expertise in design and value engineering, as well as the machining and assembly of complex, high-precision parts and modules in both small and large quantities. We also advise scale-ups on outsourcing parts of their production through our group of specialised companies, gradually and efficiently implementing these outsourcing arrangements.

Facts & Figures

Staff

ISO Certifications

AS9100 | 9001 | 14001 | 45001

Cleanroom Space

>2000 m²

Machining Hours Annually

Services

Development & engineering

We specialise in developing products that integrate mechatronics, optics and precise mechanical parts. To execute our projects, we house multidisciplinary teams of experts in mechanics, design for excellence, optics, electronics, and software. Our mission is to design functionality that meets all requirements, starting from a concept, prototype, or pre-production stage.

Our teams communicate effectively with our clients’ specialists and engage with them from an early stage to create innovative, robust, and cost-effective designs. We leverage our extensive experience in production technologies at the component and system levels to deliver modules or systems that perform as promised and are ready for production.

Parts production

Hittech Group operates facilities in the Netherlands, Germany, and Malaysia, specialising in high-end turning, milling, and electrical discharge machining. We focus on high precision and complexity for small to medium production runs, working with materials such as titanium, aluminium, steel, and high-performance alloys. Unmanned production can occur in the evening and at night using robotics, automatic tool changing, and automated supply and disposal systems.

We provide value-added services, including anodising, nickel plating, wet coating, supply chain management, assembly services, residual gas analysis, cleanroom assembly, and laser welding. For designing and producing 3D-printed parts, we collaborate with specialists in selective laser sintering and direct metal deposition.

Assembly & testing

Our assembly activities are distributed across various specialised companies, from submodules to complete products. We maintain strict quality standards by using in-house developed qualification tools tailored to specific needs, such as AS9100-certified production, CE marking, and compliance with ITAR regulations.

We possess expertise in adhesive application and optical alignment, emphasising the importance of thorough work preparation for quality and efficiency.

Supply chain management

We recognise the importance of collaboration and full traceability throughout the supply chain in serving our customers effectively. We relieve our customers' burdens by leveraging our global supply chain, which comprises qualified suppliers with diverse competencies, regulations and specialisations.

Our supply chain management also ensures that our operations scale flexibly to meet any changing demands of our customers, which will then be implemented in a controlled manner to maintain a continuous supply. We have a strong foundation of manufacturing companies and expertise in manufacturability and production technologies. Because the different Hittech Group companies are integral to the supply chain, we provide our customers with flexibility, continuity, and reliability.

Project management

We aim to ensure customers are so pleased with how their projects are carried out that they are keen to trust us with their next one. Our project teams possess a deep understanding of how to strike a balance between the quality of the final product, project costs, and the ongoing pressure of deadlines.

This balance benefits both our clients and our organisation. Across our project teams, we foster a proactive attitude and encourage open communication. This success is grounded in our extensive experience in the manufacturing industry and the continuous training we offer to our employees.

Materials

Through an ultra-fast cooling process (1,000,000 ºC/s), we can produce super-alloys which combine aluminium and silicon with a refined microstructure and enhanced properties, including damping, stiffness, strength, and natural frequency. These alloys are often used for the manufacturing of complex optical components or specific structures for use in space.

Our foundry specialises in sand casting complex products from high-quality aluminium alloys. With a modern production line that includes casting robots and computer-controlled sand preparation, we can economically produce series from a few dozen to over 10,000 pieces.

Our latest news about defence and aerospace

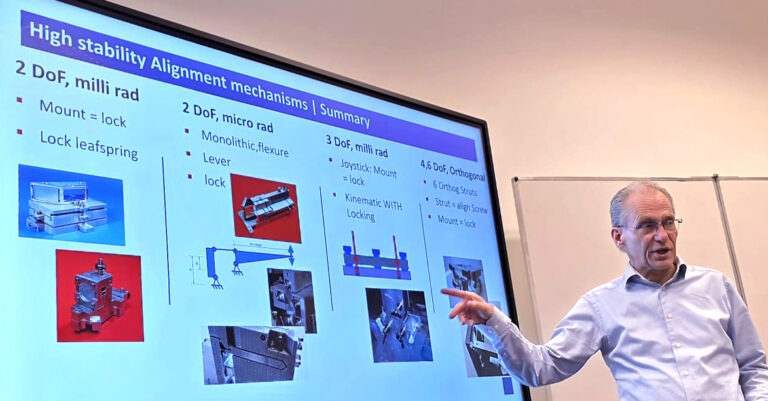

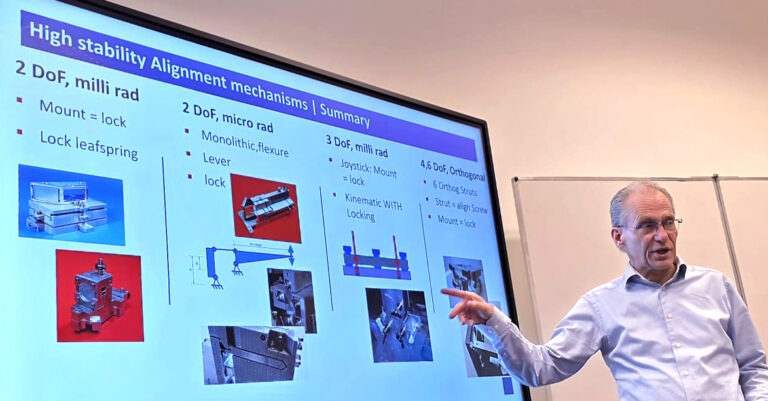

Dutch design principles for precision at LiS

Pieter Kappelhof, our Director of Technology, was invited to speak at the space instrumentation lecture programme at LiS (Leidse instrumentmakers…

Dutch Trade Mission Sustainable Aviation & Innovation Canada

This is our Business Development Manager, Martijn Leijten, at the Dutch Embassy in Toronto during the Dutch Trade Mission on…

Melt Spinning lecture at TU Delft

This is Roger Senden, ‘back’ at TU Delft, where the roots of Hittech RSP Technology lie, to discuss microstructures. “To…

How to create the perfect team of engineers?

“Personal matchmaking is the key to creating a well-balanced project team.” Over five posts, our specialists share trends and developments…

Design for Excellence from a value engineering perspective

“Value engineering, when done right, is a great alternative for outsourcing to low-cost countries.” Over five posts, our specialists share…

Cleanliness is a mindset that can be trained

“Training suppliers’ staff regularly can ensure optimal production cleanliness.” Over five posts, our specialists discuss trends and developments for 2026.…

Dutch design principles for precision at LiS

Pieter Kappelhof, our Director of Technology, was invited to speak at the space instrumentation lecture programme at LiS (Leidse instrumentmakers…

Meet our technical advisers for defence and aerospace

Contact us

"*" indicates required fields